ENERLYT is currently developing a micro-CHP with a hot gas engine based on wood pellets. This heating system is intended to supply electricity and heat to houses in the residential or commercial sector.

The use of CO₂-neutral fuels can make an important contribution to reducing the greenhouse effect. The simultaneous substitution of conventional energy sources counteracts their scarcity and increase in price. These two effects, combined with environmental compatibility and the storage effect, result in a future key role for renewable fuels.

Wood pellets are of particular importance here, as they are almost CO₂-neutral and can be used for decentralised energy generation and in drive systems. They are produced from sawmill by-products with wood as a renewable raw material that is available virtually on every doorstep. Ideally, wood should be utilised in two stages, first as a material and then as an energy source, i.e. wood should primarily be used secondarily as a heating material and first as a building material, for example. Only in this way will the CO₂ remain bound for decades beyond the life of the tree. Only wood waste should be burned.

The results of the 3rd Federal Forest Inventory from 2012 have made it clear that the volume of wood in Germany has risen to a record level. The total amount was 3.7 billion m³ of wood, making Germany the country with the most wood in Europe. Since wood reserves in Germany are very high and wood is a constantly renewable raw material, wood pellets currently offer a high degree of supply security. The use of domestic raw materials also reduces dependence on oil-producing countries. Wood pellet production creates jobs in the country and strengthens the economy.

Numerous traders now offer the valuable fuel in standardised quality at prices that have often been significantly cheaper than fossil fuels in recent years, as the price comparison by C.A.R.M.E.N e. V. proies. The price development of wood pellets is also independent of fossil fuels, making price speculation unnecessary. More favourable pellet prices can be achieved by purchasing larger quantities.

The transport of pellets is considered safer and more environmentally friendly compared to fossil fuels. No environmental disasters occur if the means of transport is damaged. Wood pellets have a high energy density of about 4.8 kWh/kg and a high bulk density, which makes storage easy and space-saving.

For existing houses, pellet heating systems are particularly interesting if the possibility to store pellets already exists. This is the case for houses with oil heating. The old oil tank can then simply be replaced by a pellet store. The breath-taking smell of oil is replaced by the smell of wood. There are also interesting possibilities for setting up a pellet store in new buildings, for example underground storage outdoors.

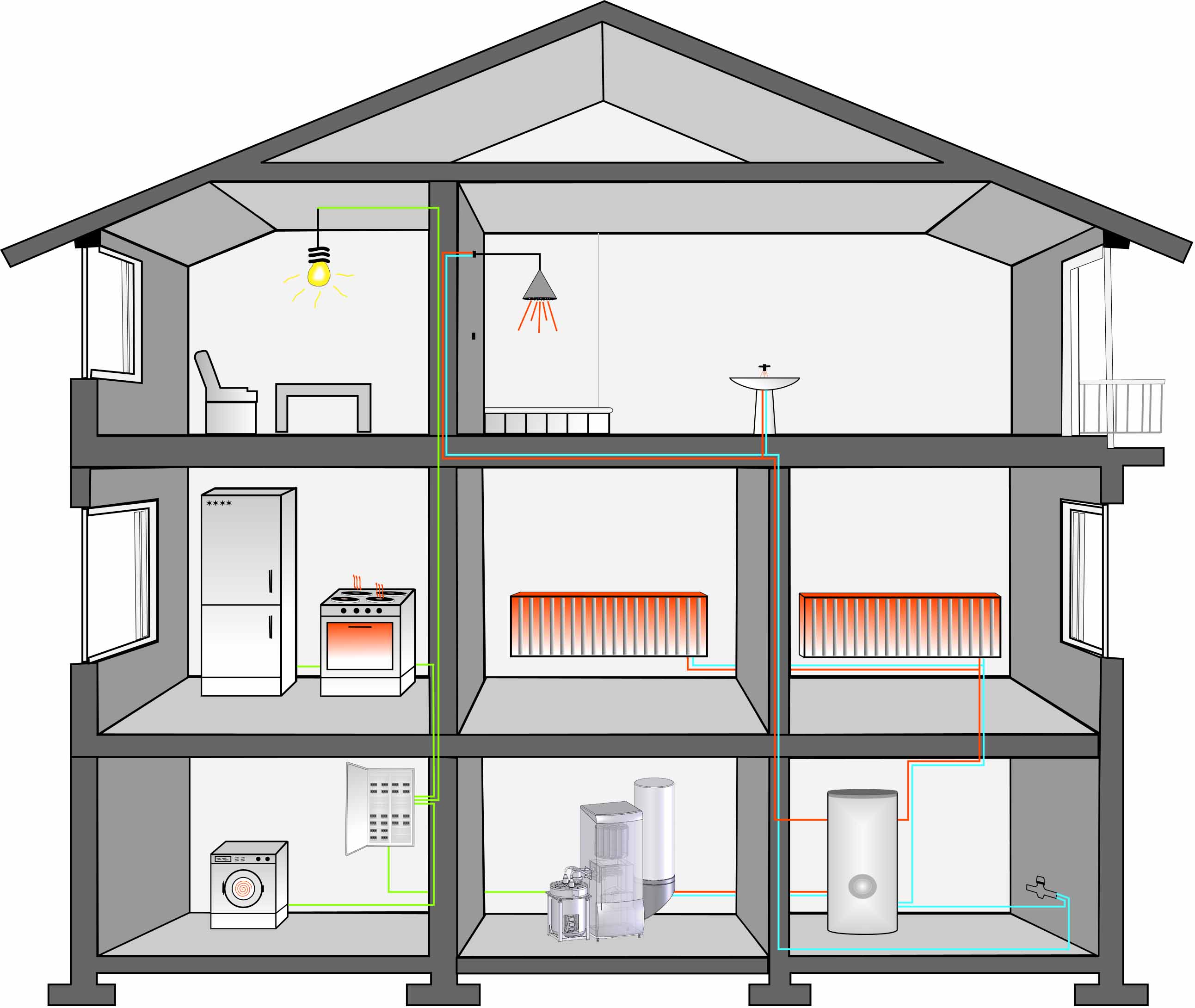

In addition to the advantages offered by the renewable fuel wood pellets, CHP is seen as an indispensable building block for the success of the energy transition due to the high fuel utilisation as well as the flexible provision of power. Our micro-CHP combines the ecological advantages of cogeneration using the hot gas engine with those of a highly efficient wood pellet heating system from the company GUNTAMATIC. The increased use of decentralised CHP plants can save power plant capacities.

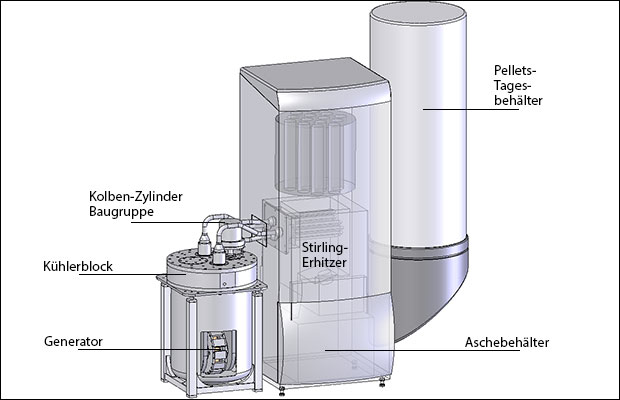

The compact micro-CHP consists of an innovative hot gas engine (2-ZGM-1 kW) and a highly efficient wood pellet boiler (BIOSTAR) from GUNTAMATIC.

The heater of the patented hot gas motor protrudes laterally into the cyclone combustion chamber of the pellet boiler. The motor is cooled by the return flow of the heating water. The Stirling process is set in motion by the heat supply on one side and the cooling of the system on the other side of the hot gas engine. The piston movements inside the machine drive a generator that produces electricity with an electrical output of approx. 1 kW. With a thermal output of approx. 3 kW at a low temperature level, the hot gas engine gives off its heat directly to the buffer tank or to a separate heating circuit.

The hot gas motor operates with 2 cycles, each of which is phase-shifted by 90°. This ensures a favourable mass- and volume-related energy density and the controllability of the system. Regenerators made of a sintered metal fibre matrix are used as intermediate heat storage in each of the 2 cycles. These were developed in a joint research project with the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research. The research project was funded by the Federal Ministry of Education and Research under the funding code 03WKO04G.

With a heat output of approx. 10 kW, the wood pellet boiler covers the peak load and provides the required heat for the building at a high temperature level.

The micro-CHP is suitable for both stand-alone and grid-connected operation.

The design output of the CHP unit is 1 kW electrical and 3 kW thermal. The system medium pressure is 8 bar. The heater temperature is 800° C, the cooler wall temperature 70° C. The overall efficiency is 93 %, the electrical efficiency 23 %.

Due to the low number of moving parts, a long service life and low potential for malfunctions are predicted. The CHP is designed as a modular compact unit for installation in a boiler room.

You can find more technical information about the hot gas engine in the flyer. You will need Acrobat Reader to view the file.

Contents

Download:

Flyer as PDF file

Of the project partners, only a few important ones should be mentioned here: the Fraunhofer-Gesellschaft, the Steinbeis Research Centre, the TU-Dresden, the ILK Dresden, the Friedrich-Alexander University Erlangen-Nuremberg (FAU) and INNOVENT e.V. Technologieentwicklung Jena.

With a slightly modified burner, the system can also be operated with EL heating oil according to DIN 51603 Part 1.

From 25 to 27 February 2010, ENERLYT was represented at the CEP “CLEAN ENERGY & PASSIVEHOUSEˮ, the international trade fair for renewable energies and passive houses, in Stuttgart. On its own stand, the innovative Stirling engine was presented, which acted as a crowd puller in operation.

Although the motor was only partially housed in a casing, visitors were able to see for themselves the low-vibration and quiet operation.

The interest was very great and generally positive. Many contacts were made.

Parallel to the trade fair event, the 3rd German Stirling Congress took place on 25. 2. 2010. Around 1,100 congress participants informed themselves about the state of the art, future perspectives and the results of current research projects on the Stirling engine.

Dr.-Ing. Andreas Gimsa, Managing Director of ENERLYT Technik GmbH, spoke on the topic of “The motor with 4 cycles and without SIEMENS, a promising machineˮ. In the lecture, the special features of the patented ENERLYT motor were explained and the difference to the SIEMENS motor was shown.

Interested parties have the possibility to download the presentation documents. You will need Acrobat Reader to view the files.

To download the file, please right-click on the link and select “Save target as ...ˮ.

Below you will find a video clip showing, among other things, the Gimsamotor®.

Licensees for novel motor sought outside Berlin/Brandenburg!

We know that potential licensees are waiting for our market innovation, we just don't know where they are yet!

Since we cannot supply the whole world with this promising machine, we are looking for companies who, like us, see the enormous market potential.

You can find more information about our offer here.

The development is headed by Dr.-Ing. Andreas Gimsa.

Dr.-Ing. Andreas Gimsa

+ 49.(0)3 31.8 88 44-0

gimsa@enerlyt.de